Accompanying with the quick economic development in China, increasing numbers of underground structures (especially tunnels) have been constructed or under construction; according to the incomplete data, more than 10,022 road tunnels, total length of which is 8,052.7 km, and 20,000 km city railway tunnels had been constructed by the end of 2012. Various tunnel performance problems (e.g., longitudinal differential settlement, segment crack and/or damage, leakage, and void behind the tunnel lining) were detected in most of the operational tunnels, these tunnel problems might be caused by either the tunnel structures themselves or operational environments. And thus, a great deal of manpower and fortunes are required to spend on the structure health inspection and repair of tunnels every year. In such a circumstance, a series of researches on the nondestructive examination (NDE) of tunnel structures, including frequency GPR technology, machine vision system and infrared detection system, have been carried out by our research group in recent years, and a fast-moving structure health inspection vehicle was developed for road and railway tunnels. Through the use of the developed fast-moving structure health inspection vehicle, the safety level of tunnel structures could be easily and quickly assessed, further, corresponding repair methods and/or techniques could be derived. The detailed research, in this aspect, that performed by our research group can be summarized as follows:

1) A ground penetrating radar (GPR)-based 3-D visualization detection method was advanced to detect the grouting behind tunnel lining for shield tunnels, it is widely acknowledged that inefficient-grouting can lead to significant ground deformation, and the detection error of proposed 3-D visualization detection method could be less 2.0 cm; and further, a ground penetrating radar (GPR)-based ground deformation control technique was developed.

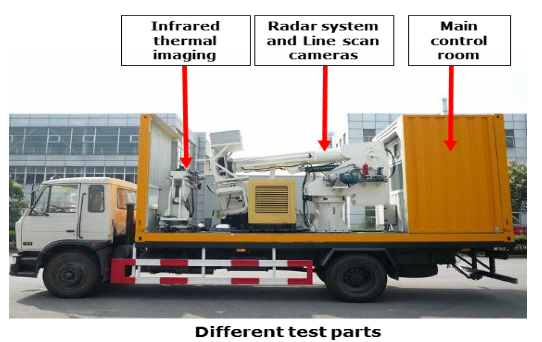

2) A fast-moving structure health inspection vehicle was developed for road and railway tunnels, in which the techniques of air-coupled radar, infrared video, and linear CCD scanning were all incorporated in. It was found that the 10.0 cm defect within 10.0 m behind the tunnel lining, 0.3 mm concrete crack on the tunnel lining, and 5.0 cm leakage in tunnel could be effectively detected by the developed structure health inspection vehicle. Further, a classification library of tunnel performance problems and a safety assessment system of tunnel structures that based upon the inspection results of the developed tunnel structure health inspection vehicle were developed.

3) A fast green concrete (GC) and textile-reinforced concrete (TRC)-based tunnel lining repairing and/or retrofitting technique was developed, which was proved to be environment-friendly, easy-to-construct, high-performance of reinforcement, and of high early strength.

The research results have been applied to various projects in China, such as Shanghai metro tunnels, Shanghai Yangtze river highway tunnel, Guangzhou Shiziyang tunnel, and many freeway tunnels in Yunnan Province, and significant economic and social benefits were achieved.

Objective

1) To realize the nondestructive examination of tunnel structures in a high-precise and fast way; 2) to assess the safety level of tunnel structures based upon the nondestructive examination results; and 3) to develop a fast tunnel lining repairing and/or retrofitting technique that could be environment-friendly, easy-to-construct, and of high early strength.

Approach

1) GPR technology, machine vision system, and infrared detection system, combined signal analysis, and image recognition were employed herein to develop the nondestructive examination technique of tunnel structures; and 2) green concrete (GC) and textile-reinforced concrete (TRC) were adopted to investigate the fast tunnel lining repairing and/or retrofitting technique.

Significant Results and Potential Impact

1) A fast-moving structure health inspection vehicle was developed for road and rail tunnels; 2) the safety level of tunnel structures could be quickly assessed; and 3) the tunnel performance problems could be repaired and/or retrofitted efficiently.

Principal Investigator:

Hongwei Huang, Yadong Xue, and Xiongyao Xie

Funding

School Science and Technology Cooperation Program of Yunnan Province (2008AD013).

Key Publication

(1) Jifei Wang, Hongwei Huang, Xiongyao Xie, Antonio Bobet. Void-induced liner deformation and stress redistribution. Tunnelling and Underground Space Technology, 2014, 40: 263-276.

(2) Pingrang Wang, Hongwei Huang. Comparison analysis on present image-based crack detection methods in concrete structures. The 3rd International Congress On Image and Signal Processing, Yantai, 2010: 2530-2533.

(3) Pingrang Wang,Hongwei Huang. Automated crack detection and measurement in tunnel lining using an integrated approach. International Symposium on Advances in Ground Technology and Geo-Information, Singapore,2011: 279-287.

Fig.1. A fast-moving structure health inspection vehicle

Fig. 2. Onsite structure health inspection of road tunnel

Fig. 3. Onsite structure health inspection of rail tunnel

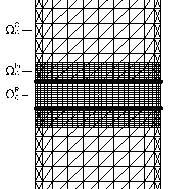

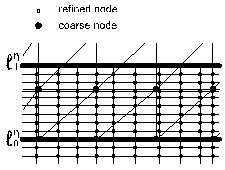

Multiscale model for long tunnels.

Multi-shaking-table test on a long immersed tunnel.

Pseudo-static Test of the Large-scale Joint of an Immersed Tunnel.