Aiming at the key issues on fire safety in the large and long tunnels and supported by National Science Foundation, National 863 Key Research Programme and Key Projects in the National Science & Technology Pillar Program, we proposed the original developments e.g. anti-fire theory and design approach of assembled tunnel lining system, the feedback theory on the properties of tunnel fire based on digitized technology and so on. Related achievements were published on the key international journals, accepted by international scholars and also applied in the key engineering like the South Hongmei Road Tunnel.

Objectives

(1)Life-cycle fire protection on the tunnel structure

(2)Feedback and digitized plan on the fire properties

(3)Multi-scale fire test system for structure

Methodology

Thermo-mechanical coupled method, multiscale theory and method, dynamic feedback technology, visualization, structure test

Significant Results and Potential Impact

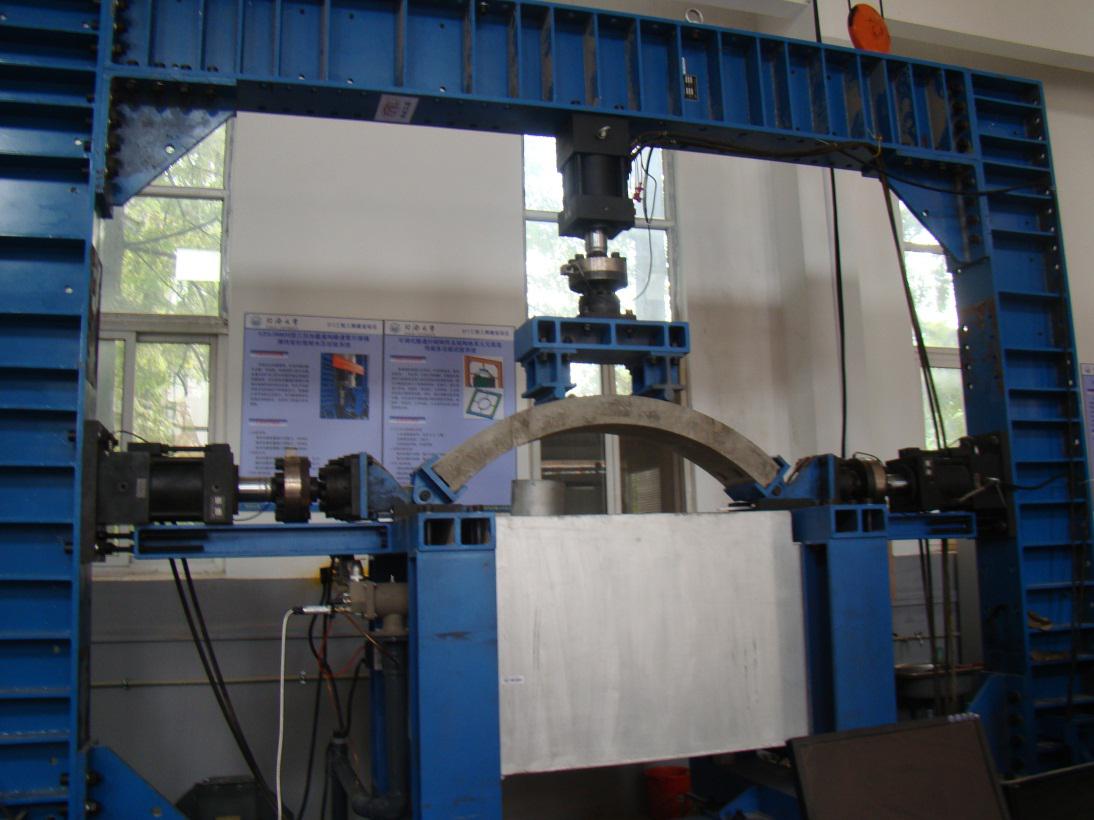

(1) The assembled tunnel lining structure faced a series of complex thermo-mechanical coupled problems (thermal induced stress, the degradation of material, discontinued system, indeterminate problem, interaction between structure and ground). We conducted multi-scale and multi-layer fire test and theory research from material scale(RC and HFRC concrete), member scale(segment and joint), and structure system scale. It was deeply revealed the progress failure mechanism in space and time scales of assembled tunnel lining structure system in fire. The calculation theory of tunnel lining segmental joint in fire during the full procedure and the influence of key parameters of ground and structure on the mechanical properties and failure modes were also proposed.

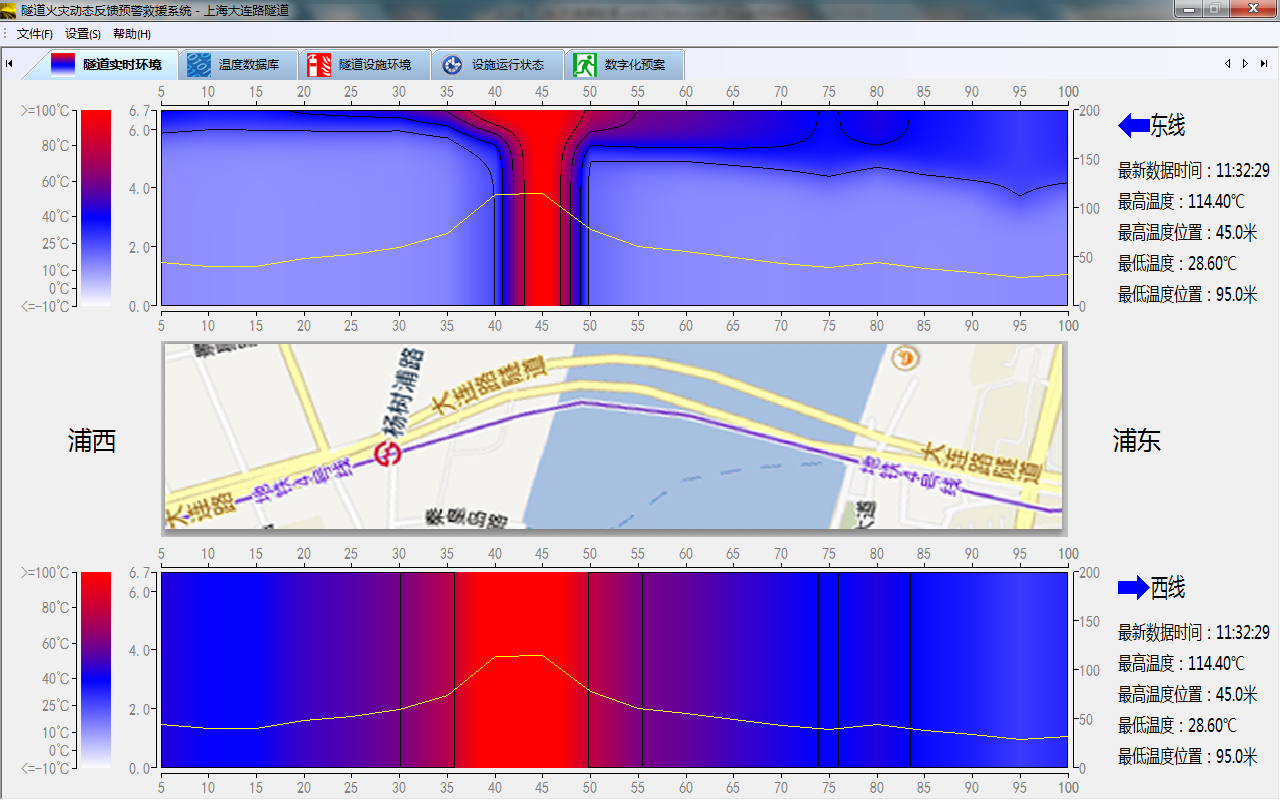

(2) Based on the research on properties and development of specific fire under the enclosed environment, the smoke feedback theory with digital technology and intelligent dynamic-feedback technology for evacuation and rescue in tunnel fire were established. The issues of dispose of fire in tunnel and underground space, evacuation and rescure and high injure & death rate were solved.

(3) The equipment and approach of lining structure in fire were innovated and test system on the mechanical properties of assembled tunnel lining structure in fire registered with independent proprietary intellectual property rights was also established.

Principal Investigators:

Hehua Zhu, Zhiguo Yan, Wenqi Ding, Xiaojun Li, Yongchang Cai, Xiaoying Zhuang.

Funding

(1) National Science Foundation of China, Single Grant (51478345), the thermo-hydro-vapo-mechanical multi-scale properties of saturated clay in fire and the effect on the tunnel structure safety

(2) National Science Foundation of China, Single Grant (50978197), research on the behavior of soft clay around the tunnel in fire and load distribution

(3) National Science Youth Foundation of China (50808137), mechanical properties and failure modes of large-diameter assembled lining structure system

(4) Key Projects in the National Science & Technology Pillar “11th Five-years plan” Program (2006BAJ27B05), technology development through engineering approaches of urban underground space.

(5) Transportation Construction Technology Program in west China (sub-programme, 200831874041), Ministry of Transportation of China, research on the fire protection approach for road tunnel lining structure

(6) National 863 Key Research Programme (2006AA11Z118), Ministry of Science & Technology of China, The key techniques of extra long and extra large diameter cross river shield tunnel

(7) Shanghai Science & Technology Commission (04DZ12010), the key technology and application for the safety of underground space under disasters.

(8) Shanghai Pujiang Talent Plan (14PJD034), the multiscale micro-&meso- description and calculation approach for the damage and mechanical properties of hybrid fiber reinforced concrete in tunnel structure under elevated temperatures

Key Publications(* denotes corresponding author)

(1)Zhiguo Yan, Hehua Zhu, J. Woody Ju, Wen-qi Ding. Full-scale fire tests of RC metro shield TBM tunnel linings. Construction and Building Materials, 2012, 36: 484-494.

(2)Zhiguo Yan, Hehua Zhu, J. Woody Ju. Behavior of reinforced concrete and steel fiber reinforced concrete shield TBM tunnel linings exposed to high temperatures. Construction and Building Materials, 2013, 38: 610-618.

(3)Wenqi Ding, Yicheng Peng, Zhiguo Yan*, Biwei Shen, Hehua Zhu, Xinxin Wei. Full-Scale Testing and Modeling of the Mechanical Behavior of Shield TBM Tunnel Joints. Journal of Structural Engineering and Mechanics, 2013, 45(3): 337-354.

(4)Hehua Zhu, Qing Chen, Zhiguo Yan*, J. Woody Ju, Shuai Zhou. Micromechanical model for saturated concrete repaired by the electrochemical deposition method. Materials and Structures, 2014, 47(6): 1067-1082.

(5)Zhiguo Yan, Qing Chen, Hehua Zhu, J. Woody Ju, Shuai Zhou, Zheng-wu Jiang. A multi-phase micromechanical model for unsaturated concrete repaired using the electrochemical deposition method. International Journal of Solid and Structures, 2013,50(24):3875-3885.

(6)Hehua Zhu, Shuai Zhou, Zhiguo Yan*, J. Woody Ju, Qing Chen. A two-dimensional micromechanical damage-healing model for microcapsule-enabled self-healing cementitious composites under tensile loading [J]. International Journal of Damage Mechanics. (DOI: 10.1177/1056789514522503)

Fig. 1 Full-scale test on the mechanical properties of assembled tunnel lining structure in fire

Fig. 2 Fire test in a large cross section tunnel

Fig. 3 Field fire test in a tunnel in high altitude

Fig. 4 Intelligent evacuation and rescue system based on dynamic feedback theory for tunnel fire

Fig. 5 Multi-function fire test system for tunnel and underground engineering