Underground construction has boomed in the last 10 years worldwide. It have continued to progress in scale, adaptability, and safety to unique difficult ground conditions, coupled with advancement of technologies. Advancement in the modern instrumentation and monitoring equipment, the use of virtual design and construction (3D/4D modeling), and a greater appreciation for risk management have all contributed toward larger, longer, safer, and more user-friendly tunnels and underground spaces that continue to present cost-effective solutions to building much-needed infrastructure. Similarly, advancements in the health monitoring methods helped advance the maintenance technology in underground engineering. Against this background, a series of researches, as summarized below, were conducted, and the research results have been applied to Shanghai metro tunnels, Shanghai Power tunnels.

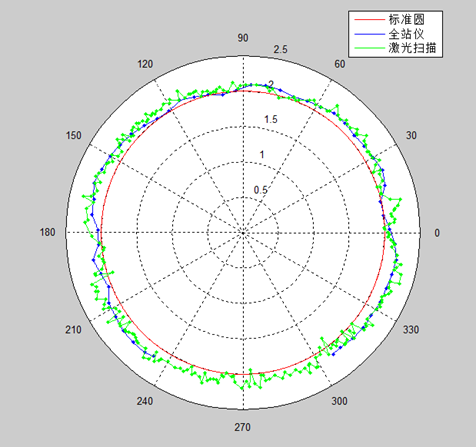

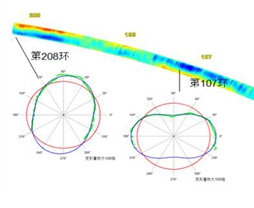

(1) The tunnel survey and monitoring technology based on terrestrial 3D laser scanning. A new approach is introduced to measure tunnel deformation by means of terrestrial laser scanning (TLS) and a 3D modeling algorithm is proposed so that the tunnel deformation is visualized. The problems about data collection and data processing are also solved. The reliability of TLS is verified and the difference between total station and TLS is less than 2 mm for tunnel deformation measurement.

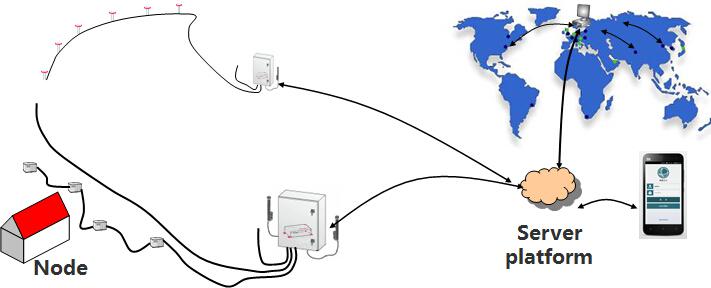

(2) Smart monitoring and online condition assessment system of tunnel. A result of information technology and micro-electro-mechanical system (MEMS) advancements, has resulted in real-time monitoring capabilities in tunnel. We can now be linked to remote locations throughout the entire construction and operation process. And vibration based assessment method is also serviced for service condition evaluation. This is proving increasingly valuable and allowing for more informed decisions out in the field.

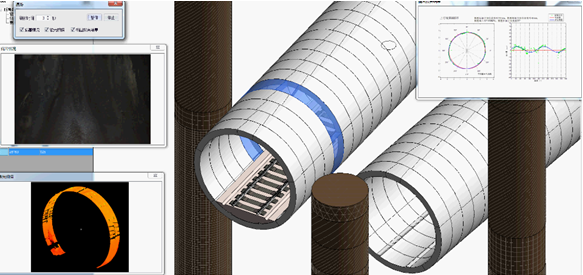

(3) The Building Information Modeling (BIM) technology application in underground engineering. The emergence of Open BIM effectively improves the interoperability of construction and maintenance information. Besides, cloud technology supports virtualization in the case of the distributed system and multi-user collaboration. Based on the cloud and the Open BIM, we have put forward the cloud services models and the cloud-based Open BIM building information services for quality, cost and schedule management in underground engineering.

Objective

1) To provide technologies and contributed toward larger, longer, safer, and more user-friendly tunnels; and to develop smart monitoring and online condition assessment system for underground structure; and 3) to provide BIM information services for underground engineering.

Approach

Software Compilation for Android/iOS/MATLAB platforms, software and hardware integration and test, model tests and field tests were simultaneously employed herein to develop new technologies for the Construction, Operation and Maintenance of Underground Engineering .

Significant Results and Potential Impact

1) A new approach is introduced to measure tunnel deformation by means of terrestrial laser scanning (TLS); 2) a smart monitoring and online condition assessment system was developed and service for Shanghai Power tunnel; and 3) we provide life-cycle BIM information services and support for Shanghai metro line 13.

Principal Investigator:

Yongsheng Li, Xiongyao Xie, Zixin Zhang, Yunjun Lai, and Biao Zhou

Funding

National 973 Basic Research Program of China (2011CB013800), and Shanghai Science and Technology Development Funds (12231200900, 13231200102).

Key Publication

(1) Xiongyao XIE, Xiaozhi LU, Development of a modeling method for monitoring tunnel deformation based on terrestrial 3D laser scanning. Chinese Journal of Rock Mechanics and Engineering, Vol.32(11), 2013:2214-2224

(2) Zhou, B; Xie, XY; Li, YS, A structural health assessment method for shield tunnels based on torsional wave speed, Science China Technological Sciences, Vol. 57(6) , 2014:1109-1120

(3) Zhou B., Xie X.Y., Yang Y.B., Jiang J.C. A novel vibration-based structure health monitoring approach for the shallow buried tunnel. CMES: Computer Modeling in Engineering &Sciences, 2012, 86(4): 321-348.

(4)Xiong-yao XIE, Hong-jie YU, Deformation control of operating tunnels induced by deep excavation of overlying metro, Chinese Journal of Geotechnical engineering, Vol. 36 (1), 2014: 88-97

(5) Xie X Y, Xie T C. Research for framework of BIM-based platform on facility maintenance management on the operating stage in metro station (ISADS), 12th International Symposium on. IEEE, 2014.

Fig. 1. Deformation monitoring technology based on terrestrial 3D laser scanning

Fig. 2. The smart monitoring and online condition assessment system and application in Shanghai Power tunnel

Fig. 3. The application of BIM in underground engineering