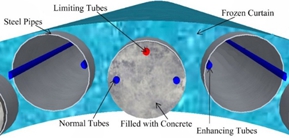

A new pre-supporting technique, Freeze-Sealing Pipe Roof method (FSPR), has been put forward, which combines Pipe-Roofing Method and Artificial Ground Freezing method (AGF). The Gongbei Tunnel, a major part in Zhuhai Link of Hong Kong-Zhuhai-Macao Bridge, is going to employ the FSPR method for the first time in China.

Objective:

Research on the freezing effect of the freezing scheme of FSPR and its control method by large scaled physical model. Study on the mechanical property of composite structure, which consists of mechanical property of materials and contact surface. To verify the feasibility of the recommended freezing scheme of FSPR, a numerical simulation is carried out for active and maintaining freezing stages.

Approach:

Large-Scale Physical Model Test:

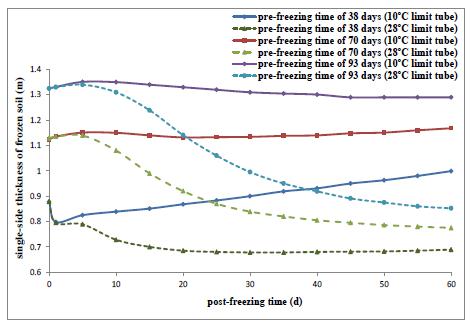

An innovative freezing scheme for the FSPR method is created with three kinds of freezing tubes (normal, enhancing and limiting tubes). By controlling of the switching time of the three kinds of freezing tubes and the temperature of the enhancing and limiting tubes, the temperature field changes is analyzed in the three stages of before excavation, excavation and lining construction.

Steel Pipe-frozen Soil Composite Structure Model Test:

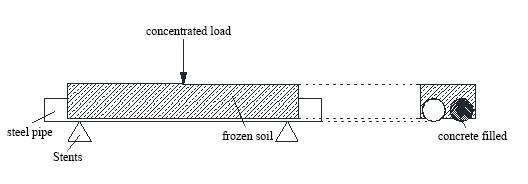

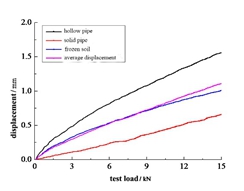

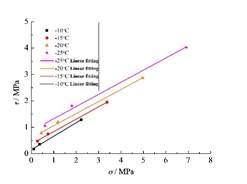

A model test of steel pipe-frozen soil composite structure was conducted. From the test, how the displacement of steel pipes and frozen soil between the pipes varied with loading was obtained. Contact surface shear test of the composite structure was conducted to obtain the ultimate normal stress and tangential stress at different angles and temperatures.

Numerical Simulation:

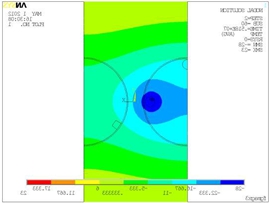

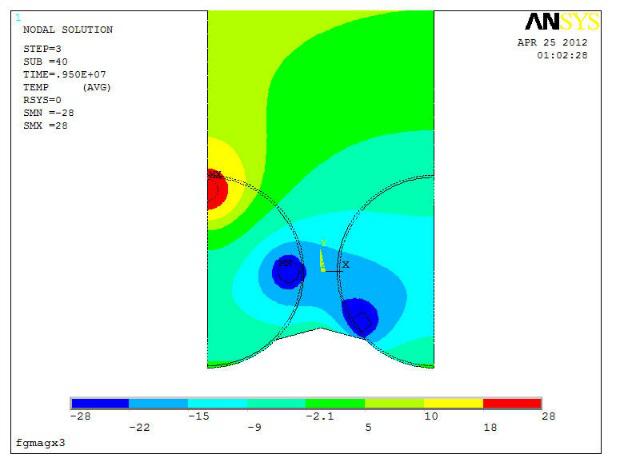

Taking the development of temperature field, the resisting ability of the frozen ground curtain to thermal disturbance resulted from excavation, and the control of frost heave as criteria, analysis of different freezing schemes by numerical simulation is carried out for active and maintaining freezing stages.

Significant Results and Potential Impact:

Large-Scale Physical Model Test:

The test results indicate that the development of the freezing curtain shows the expected law and works well. The freezing curtain was formed between the pipes of pipe-roof and achieved good water sealing effect. It evaluates the safety and rationality of the freezing scheme. What is more, these data are valuable as a reliable basis for the evaluation of FSPR.

Steel Pipe-frozen Soil Composite Structure Model Test:

The deformation capacity of frozen soil following steel pipe is related to temperature. When a suitable temperature is reached, the deformation capacity of frozen soil following steel pipe is the best. It should be considered when the average temperature of the frozen soil is designed in practical project. Contact surface shear strength envelopes at different temperature were fitted. Therefore, whether slip between steel pipe and frozen soil occurs can be determined in numerical simulation of real model.

Numerical Simulation:

It can be concluded that FSPR is capable to form a sustainable and stable waterproof curtain, and has good construction maneuverability. With the arrangement of enhancing pipes and limiting pipes, the freezing scheme can effectively resist the impact of thermal disturbance of excavation and limit the development area of frozen soil curtain to control the frost heave amount. The recommended freezing scheme of FSPR is reasonably practicable.

Principal Investigator:

Xiangdong HU

Large-Scale Physical Model Test:

Schematic diagram of FSPR

|  |  |

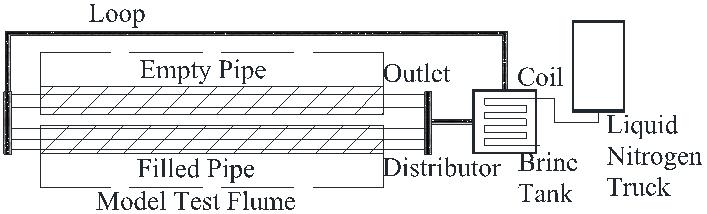

| Schematic diagram of the freezing system of the Large-scale Physical model |

|  |  |  |

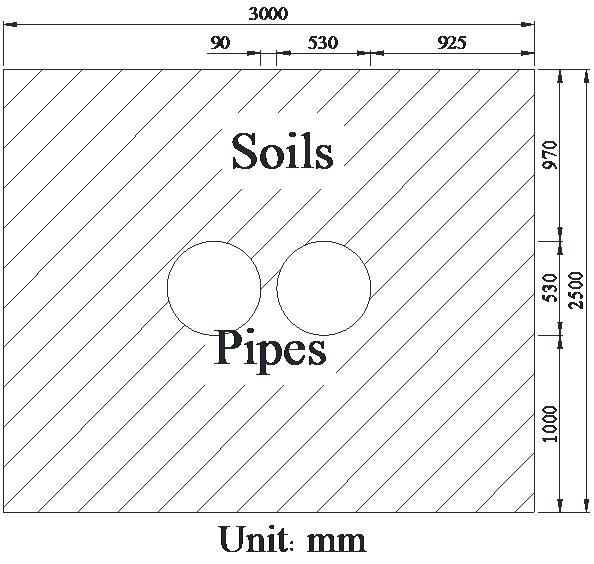

| Design drawing and modeling site |

Steel Pipe-frozen Soil Composite Structure Model Test:

Longitudinal force model of composite structure

|  |  |

| Sample of bearing capacity test after demoulding | Loading device of bearing capacity test |

|  |  |

Load-displacement curve and shear strength envelop curve

Numerical Simulation:

|  |  |

| Temperature contours (pre-freezing 65days, freezing scheme B) | Temperature contours (pre-freezing 65 days, post-freezing 40days, limiting tube with 28°C, freezing scheme B) |

|  |  |

| Temperature development of point G of maintaining freezing stage (freezing scheme B) | Frozen soil development of maintaining freezing stage (freezing scheme B) |