(1)TBM Tunnelling in Soft Ground

In recent years, several large size shield tunnels have been constructed in urban areas at shallow depth with the increasing practical demands, such as accessibility, serviceability and economy. The Groene Hart Tunnel, completed in 2005 in the Netherlands, was constructed using a slurry shield machine with an outside diameter of 14.87 m. The M-30 Tunnel in Madrid excavated by Earth Pressure Balance (EPB) shield machine, 15.2 m in diameter, was until recently the biggest shield tunnel completed in the world. In September 2006, two massive 15.43 m diameter slurry shield machines began work on the Shanghai Yangtze River Tunnel. Thus, in recent years, more and more attention has been paid to the face stability of large shield-driven tunnels. For given ground conditions, what is the maximum dimension that we could build with our present shield construction technology? Is the failure mechanism of extra large shield tunnels still the same as smaller or normal size ones? When does size count? These questions need to be answered by today’s engineer.

(2)TBM Tunnelling in Jointed and Faulted Rock Mass

With the application of TBM in the construction of tunnels, increasing simulations are taken on TBM tunnels. We proposes the concept of utilizing block theory to simulate TBM tunnels in discontinuous rock masses and predicate the stability of surrounding rock blocks in TBM tunnels for the first time in the world. Besides, the basic theory of the simulation on TBM tunnels with the block theory has been established through three parts: simplification of thrust and torque from the cutterhead, block classification of TBM tunnels and simulation on the excavation progress. Also, a simplified model of TBM tunneling has been established based on the software BLKLAB (coded by our research group) so as to simulate the progress of TBM advancing and to predicate the stability of surrounding rock blocks.

Objective

To reveal and visualize the performance TBM tunneling in difficult ground; and 2) to advance TBM performance predicting model and smart TBM tunnelling system.

Approach

Key block theory, model tests and field tests were simultaneously adopted herein to study the performance of TBM tunnelling.

Significant Results and Potential Impact

1) The TBM tunneling performance in difficult ground could be efficiently analyzed and visualized based upon a novel model, and a smart and robust TBM tunnelling system, which was based upon BLKLAB, was developed.

Principal Investigator:

Zixin zhang, Yongsheng Li, Xiongyao Xie, Yunjin Lai, and Biao Zhou.

Funding

National Natural Science Foundation of China (41172249), National Natural Science Foundation of China (41372276), National 973 Basic Research Program of China (2014CB046905).

Key Publications

[1] Chao Liu, Z.X. Zhang, Richard A. Regueiro. Pile and pile group response to tunnelling using a large diameter slurry shield – Case study in Shanghai,Computers and Geotechnics 59 (2014) 21–43

[2] Z. X. Zhang, Huan Zhang. A case study on the behaviour of shield tunnelling in sandy cobble ground. Environ Earth Sci (2013) 69:1891–1900

[3] Z. X. Zhang, Q. H. Lei,A Morphological Visualization Method for Removability Analysis of Blocks in Discontinuous Rock Masses. Rock Mech Rock Eng, online 2013, DOI 10.1007/s00603-013-0471-y

[4] Z.X. Zhang, Q.H. Lei. Object-oriented modeling for three-dimensional multi-block systems. Computers and Geotechnics ,2012,48,208-227

[5] Z.X. Zhang, Y. Xu, P.H.S.W. Kulatilake, X. Huang. Physical model test and numerical analysis on the behavior of stratified rock masses during underground excavation, International Journal of Rock Mechanics and Mining Sciences, 2012(1),134-147.

[6] Z.X. Zhang, X.Y. Hu, Kieffer D.Scott, 2011. A discrete numerical approach for modeling face stability in slurry shield tunnelling in soft soils. Computers and Geotechnics 38, 94-104(SCI)

[7] Z. X. Zhang, P.H.S.W. Kulatilake, A new stereo-analytical method for determination of removal blocks in a discontinuous rock mass, Int. Jour. of Numerical and Analytical Methods in Geomechanics,2003:27:791-811

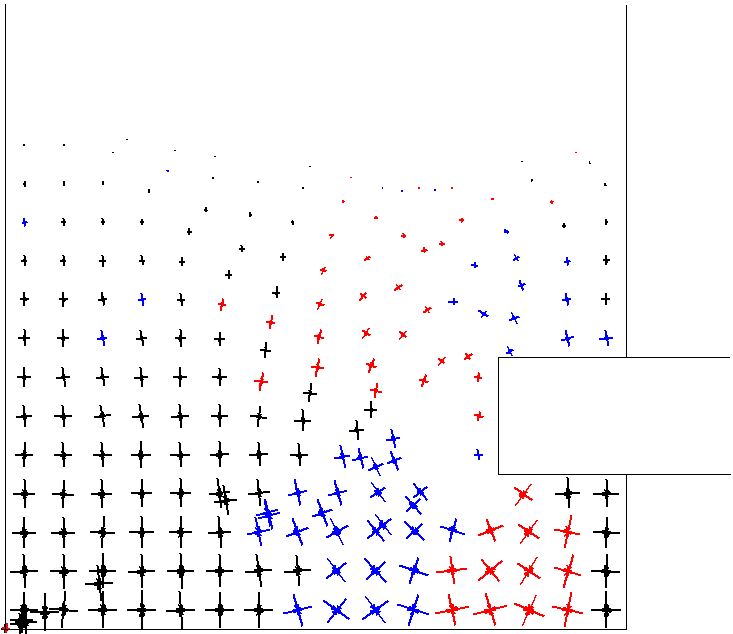

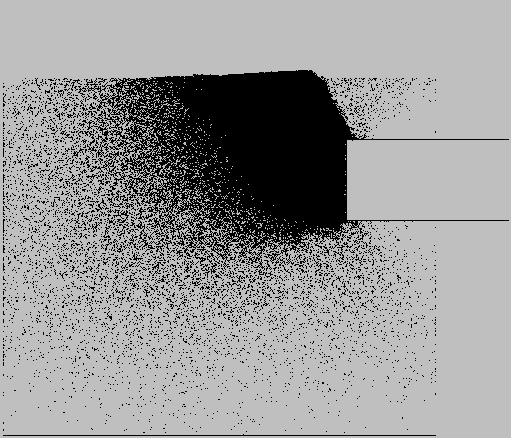

Fig.1 The two considered types of partial failure mechanisms

(a) Displacement field (b) (colour) Stress field

Fig.2 Face collapse due to insufficient face pressure (C=2.10D)

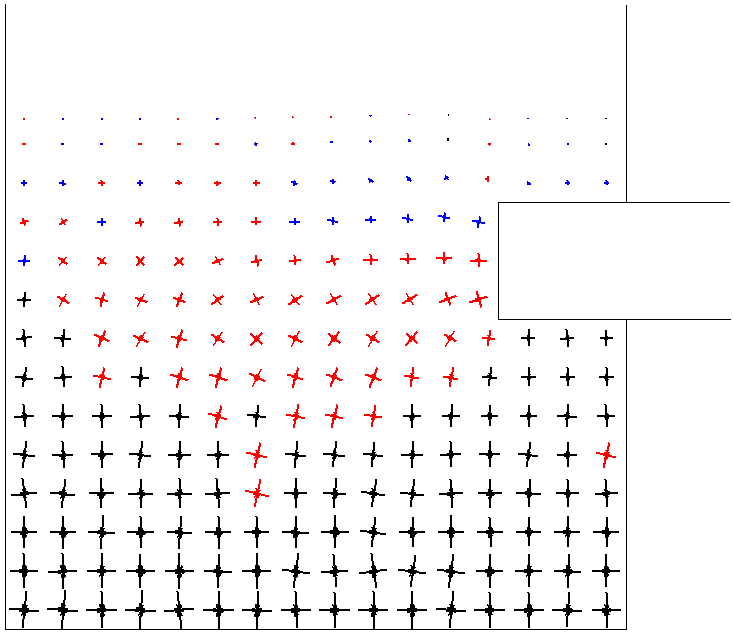

(a) Displacement field (b) (colour) Stress field

Fig.3 Face blow-out due to excessive face pressure (C=0.77D)

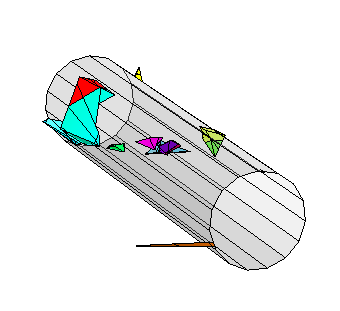

(a) (b)

(c) (d)

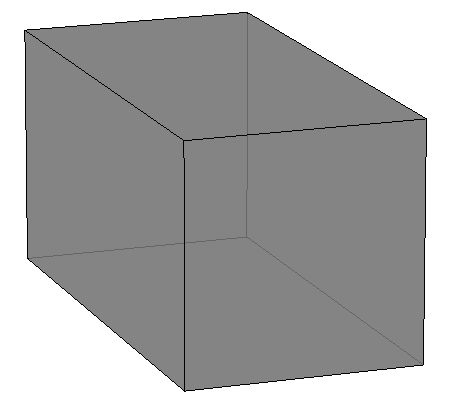

Fig.4. Constructing progress of a traditional tunnel model:

(a) definition of a computational domain; (b) construction of the multi-block system; (c) excavation of a tunnel; (d) removable blocks’ identification

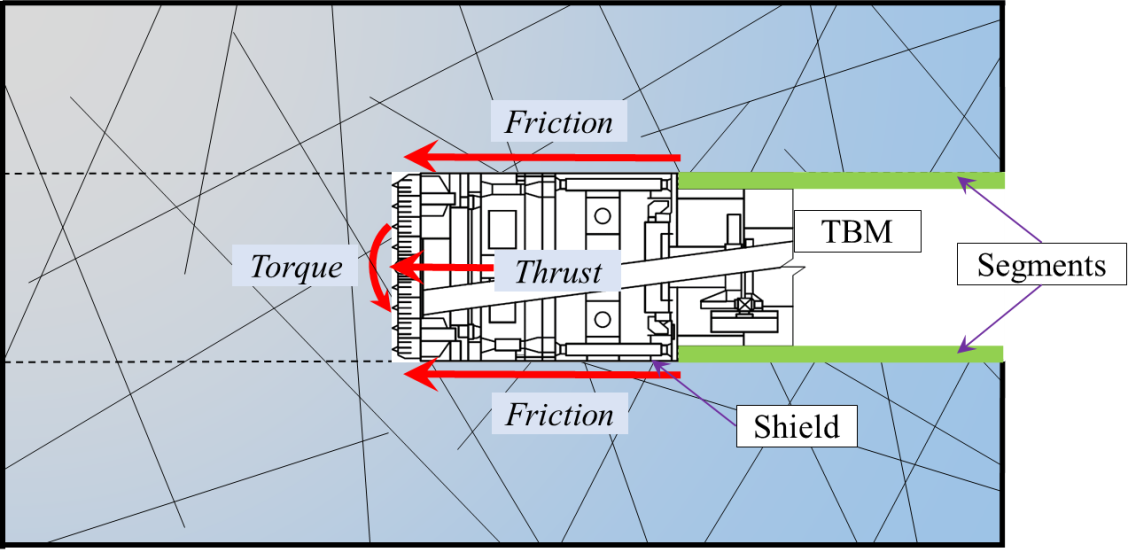

Fig.5. Forces acting on the tunnel face and periphery

(b)

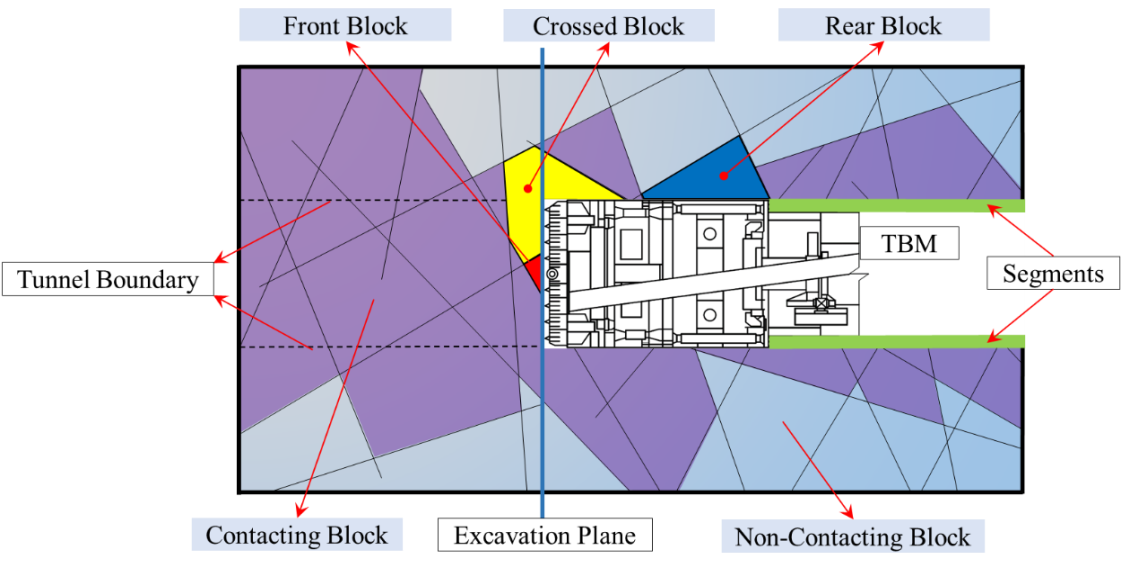

Fig.6. Diagram of the block classification in a TBM tunnel:

(a) tree structure of block classification; (b) complete block classification